Agrilab Technologies Inc. (AGT), Enosburg Falls, Vermont, recently installed its compost heat recovery system at Vern-Mont Farm in Vernon, Vermont. The Drum Dragon 200 system generates continuous combustion-free hot water from the aeration exhaust of an aerobic rotary drum compost system, reducing propane use on the farm for milk-parlor washing.

“We installed the composting drum last year and I kept looking at all that hot exhaust steam coming out of the drum thinking there must be something we can do with that heat, and then we learned about Agrilab Technologies,” says Jeff Dunklee, co-owner of the farm. “We’re impressed with how quickly and easily this Drum Dragon system was installed by Agrilab Technologies, but we’re even more impressed by the 150-degree hot water the system is sending to our milk parlor.”

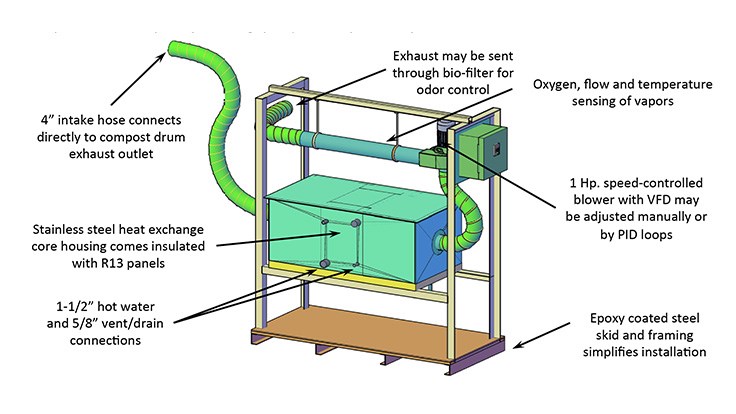

The Drum Dragon 200 compost heat recovery system is designed specifically for rotary drum compost systems. It can capture up to 120,000 Btu per hour continuously, depending on the size of the drum it is connected to and the amount of hot water being used on the site.

A computerized web-connected data system tracks real time water temperatures and other operational data points, making it easy to track performance or adjust aeration fan speeds to increase or decrease the hot water produced, the company says. Typical compost exhaust vapor temperatures range between 140 degrees Fahrenheit and 160 degrees Fahrenheit, with hot water temperatures up to 150 Fahrenheit.

The amount of heat recovered by the Drum Dragon varies depending on the hot water use patterns at the farm. At the Vern-Mont Farm, the Drum Dragon pre-heats a 120-gallon tank of water to up to 150 degrees Fahrenheit. The farm’s hot water demand cycle results in an average of 30,000 Btu per hour of continuous heat recovered.

The energy that can be captured by a Drum Dragon 200 can be worth more than $15,000 per year compared to $1.20 per gallon propane prices, depending on hot water use patterns of the site, the company says. With existing financing programs this technology can be immediately cash-flow positive for farms, saving money to help offset low milk prices and other financial pressures on dairy farms.

“We are excited to be helping farms and compost operations save money while reducing fossil fuel dependence and improving soil fertility for sustainable agriculture and watershed protection,” says Brian Jerose, president of AGT. “We’ve proven that compost heat recovery can be a cost effective and reliable form of renewable energy that also supports sustainable agriculture by producing high value compost.”