Conferences

Renewable Energy from Waste Conference features big names in corporate sustainability

The second annual Renewable Energy from Waste Conference, Nov. 17-20 in San Jose, California, brings together the most relevant companies from the private sector that are making strides in waste conversion. These leaders in sustainability are incorporating technologies into their operations that are reducing waste going to landfills while offsetting the use of fossil fuels.

During the session, “Corporate achievements in waste conversion,” attendees will hear how waste-to-energy (WTE) is part of Detroit-based General Motor’s strategy to reduce waste and produce energy from renewable sources. The company’s goal is to produce 125 megawatts of renewable electricity by 2020. Through initiatives involving WTE and landfill gas projects, the company is well on its way toward achieving that goal. Attendees will hear from Rob Threlkeld, GM global manager of renewable energy and John Bradburn, GM manager of waste reduction efforts, for an overview of all the company has accomplished.

During the session, “Corporate achievements in waste conversion,” attendees will hear how waste-to-energy (WTE) is part of Detroit-based General Motor’s strategy to reduce waste and produce energy from renewable sources. The company’s goal is to produce 125 megawatts of renewable electricity by 2020. Through initiatives involving WTE and landfill gas projects, the company is well on its way toward achieving that goal. Attendees will hear from Rob Threlkeld, GM global manager of renewable energy and John Bradburn, GM manager of waste reduction efforts, for an overview of all the company has accomplished.

Also speaking as part of the panel is Mandi McKay, sustainability coordinator, Sierra Nevada, Chico, California. She will discuss how the craft brewery is offsetting the use of natural gas by producing energy from a waste byproduct produced from the brewing process. The system has been operating successfully for several years, producing heat for the brewing process.

Michael Van Brunt, director of sustainability for Morristown, New Jersey-based Covanta, and Christina Bosch Ladd, senior sustainability manager, Keurig Green Mountain, Waterbury, Vermont, will give a joint presentation during the session on the partnership the two companies have formed to compost and anaerobically digest coffee grounds from K-cups while using the K-cups as a fuel source in Covanta’s WTE plants.

Moderated by Renewable Energy from Waste magazine Managing Editor Kristin Smith, this session brings the best examples the private sector has to offer in the way of sustainable strategies that incorporate energy from waste.

More information about the conference is available at www.REWConference.com.

Mass burn/Incineration

Wheelabrator sold to private equity firm

Waste Management Inc. (WM), headquartered in Houston, has agreed to sell its Wheelabrator Technologies Inc. (WTI) division to an affiliate of the private equity firm Energy Capital Partners (ECP) for $1.94 billion. Wheelabrator owns or operates 17 waste-to-energy (WTE) facilities and four independent power-production facilities in the U.S.

The division being sold processes more than 7.5 million tons of waste and has a combined electric generating capacity of 853 megawatts. Wheelabrator also operates four ash monofill landfills, three transfer stations and an ongoing development and construction project in the United Kingdom.

Along with the sale of the assets, Waste Management has entered into a long-term agreement to supply waste to certain WTI facilities.

“This transaction aligns with our goal of driving shareholder value by maximizing our focus on our core business and reducing earnings volatility related to electricity sales,” says David Steiner, president and CEO of Waste Management. “We look forward to a long-term partnership with ECP through our waste supply agreement.”

Steiner continues, “We appreciate the hard work and dedication of our Wheelabrator employees. They made our waste-to-energy business successful, and we anticipate that the business will continue to be successful under ECP’s ownership.”

The transaction, subject to Federal Energy Regulatory Commission approval and other customary closing conditions, is expected to close in late 2014.

Mass burn, Landfill gas

DOE makes up to $4 billion in loan guarantees available for renewable energy

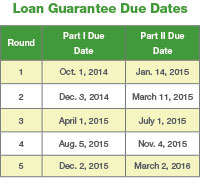

The U.S. Department of Energy (DOE) Loan Programs Office (LPO) recently issued a Renewable Energy and Efficient Energy Projects Loan Guarantee Solicitation, which would make as much as $4 billion in loan guarantees available to support innovative, renewable energy and energy efficiency projects in the U.S. that reduce, avoid or sequester greenhouse gases. The solicitation is intended to support renewable energy and energy efficiency technologies that are catalytic, replicable and market-ready.

DOE says loan guarantees can be an important tool to commercialize innovative renewable energy and energy efficiency technologies because these projects may be unable to obtain full commercial financing because of the perceived risks associated with technology that has never been deployed at commercial scale.

DOE says loan guarantees can be an important tool to commercialize innovative renewable energy and energy efficiency technologies because these projects may be unable to obtain full commercial financing because of the perceived risks associated with technology that has never been deployed at commercial scale.

The solicitation seeks applications for projects that cover a range of technologies, including waste-to-energy technologies, such as those using “methane from landfills or ranches via biodigesters.”

Applications will undergo a two-part review. The Part I submission provides DOE with a description of the project; technical information; background information on management, financing, construction, and operating strategies; and progress to date of critical path schedules. Part I determines initial eligibility of a project and whether it is ready to proceed. Applications that clear Part I then proceed to Part II, which includes the full application process.

More information is available on the Loan Programs Office website: http://energy.gov/lpo/services/solicitations/renewable-energy-efficient-energy-projects-solicitation.

Anaerobic digestion

Roeslein Alternative Energy and Smithfield Foods collaborate on Missouri AD project

Construction is underway in Northern Missouri on an $80 million renewable energy project, developed and constructed by Roeslein Alternative Energy LLC (RAE), St. Louis, in collaboration with Murphy-Brown of Missouri LLC (MBM) the livestock production subsidiary of Smithfield Foods Inc., Smithfield, Virginia.

Crews are installing impermeable covers on 88 existing lagoons to harvest biogas, also called renewable natural gas (RNG), from MBM hog finishing farms using anaerobic digestion (AD) technology developed and installed by RAE. The project is the largest of its kind, the company says, using manure from one of the biggest concentrations of finishing hogs in the Midwest to create several hundred million cubic feet of RNG annually for regional distribution.

Crews are installing impermeable covers on 88 existing lagoons to harvest biogas, also called renewable natural gas (RNG), from MBM hog finishing farms using anaerobic digestion (AD) technology developed and installed by RAE. The project is the largest of its kind, the company says, using manure from one of the biggest concentrations of finishing hogs in the Midwest to create several hundred million cubic feet of RNG annually for regional distribution.

Impermeable synthetic covers will be placed on existing nutrient treatment lagoons where barn scraper technology will deliver raw nutrients of livestock manure to covered lagoons. The covers turn the lagoons into anaerobic digesters, where naturally occurring microorganisms decompose the manure in an oxygen-free environment.

Biogas rises to the top where it will be collected and cleaned of impurities. What remains is more than 98 percent methane with approximately the same chemical composition as natural gas that can be used for vehicle fuel or injected into the natural gas grid system. The undigesteable solid residue can be used by local farmers as a natural fertilizer and the water can be safely used for irrigation.

“We are excited to see the results of our collaboration with Smithfield and Murphy-Brown begin to take shape,” says Rudi Roeslein, president of RAE and CEO of Roeslein & Associates, a systems integration company specializing in modular construction.

Transportation fuels

SG Preston to build $400 million renewable diesel plant in Ohio

SG Preston (SGP), a Philadelphia-based biofuels company, is planning a $400 million renewable diesel plant in Lawrence County, Ohio. It is designed to produce 120 million gallons renewable diesel. The SGP South Point facility also is expected to create 100 permanent jobs and be the world’s largest purpose-built producer of renewable diesel upon completion, estimated to occur in 2017, according to the company.

SG Preston describes itself as a fully integrated developer and operator of sustainable bioenergy fuelstocks, products and waste-to-bioenergy systems worldwide.

A key component of the facility’s development is the licensing by SGP of advanced process technology that has been proven at commercial scale at other locations, SGP says. The technology converts waste feedstock into renewable diesel, which the company says is chemically identical to petroleum-based diesel and can be used as a drop-in replacement in vehicles with no modifications.

SGP customizes its biofuel offering by adjusting fuel characteristics to meet various operating environments (extreme cold or heat) of the end user without diluting energy content in the fuel blend. This technologically advanced process also delivers life cycle reduction in greenhouse gas emissions compared with diesel from petroleum.

Other partners in the project include the Lawrence County Economic Development Council, which is investing 62 acres in land and other incentives. The Appalachian Partnership for Economic Growth and JobsOhio were also instrumental in securing the investment and technology.

“For SG Preston, this is an important milestone and part of a larger vision of partnering with leading, global refining technology partners and local communities to develop a portfolio of renewable diesel and renewable jet fuel refineries targeting 1.2 billion gallons per year, or 20 percent of the federal RFS2 (Renewable Fuel Standard) biomass-based mandate for biofuels,” says R. Delbert LeTang, CEO of SGP.

Pre-engineering studies for the facility are expected to begin in September 2014, with commercial operations targeted for 2017.

Plastics to oil

Agilyx to deploy new version of plastics-to-fuel technology

Agilyx Corp., Beaverton, Oregon, has announced plans to transition a Portland, Oregon, waste plastics-to-oil facility to its latest Agilyx Generation 6 technology.

The facility, which opened in early 2013 as a Waste Management-owned operation, has been using the Agilyx Generation 5 batch system. Agilyx is nearing completion of its new continuous feed technology in its Tigard, Oregon, R&D Center. The North Portland facility, known as Wastech, is expected to be the first commercial deployment of the new version of the technology.

“We are delighted to have the opportunity to launch our new technology in Portland and look forward to continued cooperation with Waste Management, who has been a supportive partner during our development stage,” says Agilyx Chairman and Chief Executive Officer Ross M. Patten. “The new facility has the capability of becoming a great solution for waste plastics as the region moves forward with zero-waste initiatives.”

“We are delighted to have the opportunity to launch our new technology in Portland and look forward to continued cooperation with Waste Management, who has been a supportive partner during our development stage,” says Agilyx Chairman and Chief Executive Officer Ross M. Patten. “The new facility has the capability of becoming a great solution for waste plastics as the region moves forward with zero-waste initiatives.”

Agilyx says the transition process is expected to be completed in the fourth quarter of 2015, with the facility designed to handle 50 tons of waste plastic per day with a production target of 10,000 gallons of crude oil daily. The upgraded facility is expected to create 30 jobs, the company adds. In addition, this will mark the first Agilyx-owned and -operated facility that will be open to commercial plastic generators and aggregators.

Founded in 2006, Agilix says it uses a patented, scalable and versatile technology that minimizes carbon impacts. Agilyx claims to enhance recovery and zero-waste initiatives by turning waste plastic disposal costs into high-quality oil revenue streams. The company’s systems are often deployed with industrial and municipal waste plastic generators and aggregators.